Addition provides end-to-end design and additive manufacturing, delivering competitive advantage for customers through uniquely innovative products, components, and devices.

What do you need help with?

About Addition

Addition provides end-to-end design and additive manufacturing, delivering competitive advantage for customers through uniquely innovative products, components, and devices.

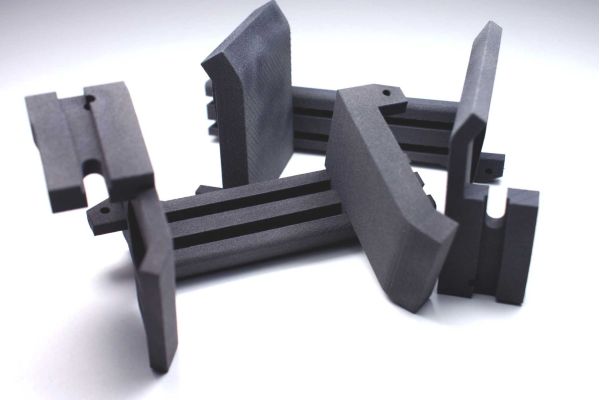

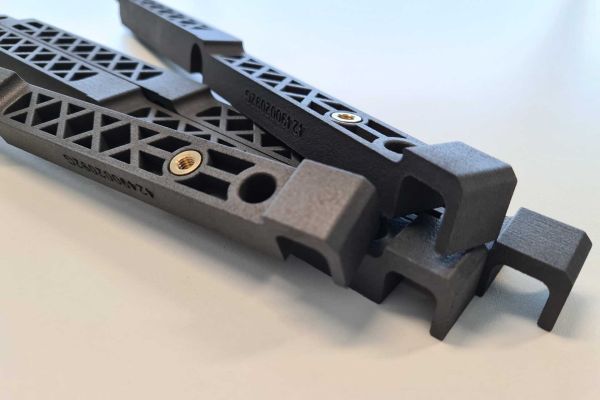

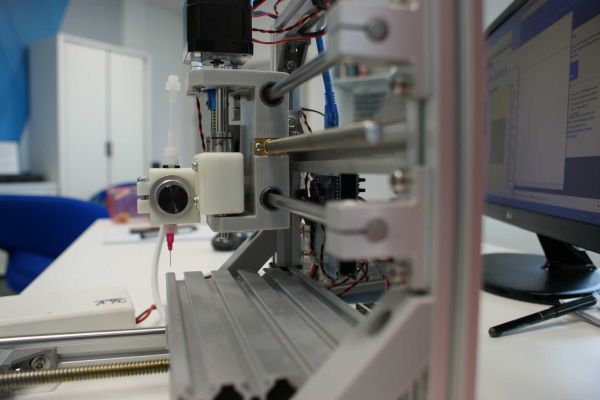

We design and manufacture solutions that unlock the power of industrial 3D printing for medical, industrial, food, pharmaceutical, sports and consumer goods markets.

We have over 25 years of industrial design and additive manufacturing expertise, ranging from consumer goods to industrial products and medical devices as well as several patents in 3D printing.

Latest News

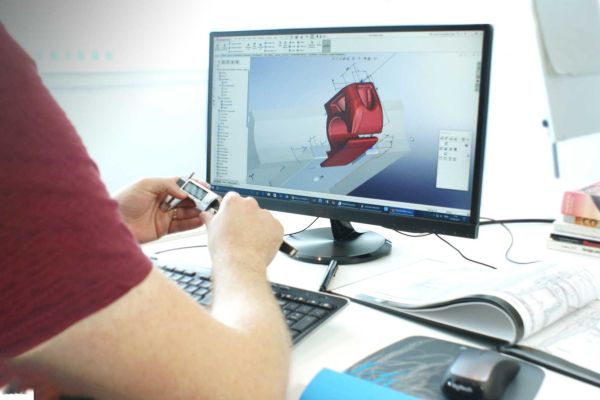

End-to-end design & Additive Manufacturing

Addition, based in Sheffeld, provides an end-to-end solution taking you from design to manufacture of a range of engineering components, format parts and change parts for automated production lines.